The LED lighting thermal path efficient heat dissipation process is one of the most critical aspects of modern lighting design. While LEDs are widely praised for their energy efficiency and long lifespan, their performance depends heavily on how well excess heat is managed. Without proper thermal control, even the most advanced LED chips will degrade quickly, leading to dimming, discoloration, or complete failure.

In this comprehensive guide, we’ll explore what a thermal path is, why it matters, and the strategies engineers use to optimize heat dissipation in LED lighting systems. Whether you’re an electrical engineer, a lighting designer, or simply curious about the technology behind LEDs, this article will walk you through everything you need to know.

What Is the LED Thermal Path?

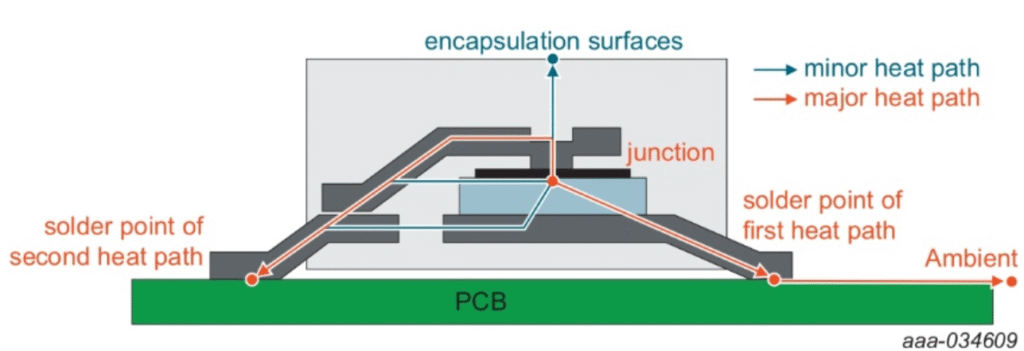

The thermal path in LED lighting refers to the complete route that heat takes as it moves away from the LED junction (the source of heat) to the surrounding environment, where it can be safely dissipated.

- Junction → The semiconductor inside the LED chip where light is generated and heat builds up.

- Package → Encapsulation materials and bonding layers that transfer heat outward.

- Heat Spreader / Substrate → Conductive layers that move heat across a wider surface area.

- Heat Sink → A metallic component (often aluminum) that disperses heat into the air.

- Ambient Environment → The surrounding air where heat is ultimately released.

Each of these stages in the thermal path plays a crucial role in keeping the LED at safe operating temperatures.

Why Efficient Heat Dissipation Matters in LEDs

Unlike traditional incandescent bulbs that radiate heat outward, LEDs are compact devices. They generate heat at the junction but do not naturally release it into the air. If that heat is trapped, it can cause:

- Reduced Luminous Output – LEDs lose brightness as junction temperature increases.

- Color Shifts – Excess heat alters the wavelength of emitted light, causing inconsistent colors.

- Shortened Lifespan – Prolonged high temperatures accelerate material degradation.

- Electrical Instability – Overheating may cause fluctuating current draw and component failure.

According to Cree Lighting’s technical guide, a 10°C rise in LED junction temperature can cut the LED’s life expectancy nearly in half. This underscores why managing the LED lighting thermal path for efficient heat dissipation is vital.

Key Components of the LED Thermal Path

1. The LED Junction

The junction temperature (Tj) is the most important thermal measurement in LEDs. Manufacturers typically specify maximum Tj limits (often between 120°C and 150°C). The goal of a good thermal path is to keep Tj well below that threshold.

2. Packaging Materials

The LED chip is mounted onto substrates like:

- Ceramic packages – Excellent thermal conductivity but higher cost.

- Metal-core PCBs (MCPCBs) – Widely used in LED modules, balancing cost and heat transfer.

- Plastic-based substrates – Cost-effective but with lower thermal performance.

3. Thermal Interface Materials (TIMs)

Materials like thermal pastes, pads, or adhesives fill microscopic air gaps between surfaces, improving conduction from the LED to the heat sink.

4. Heat Spreaders and Heat Sinks

- Heat spreaders (copper or aluminum plates) distribute heat evenly.

- Heat sinks feature fins that maximize surface area, allowing better convection.

5. Ambient Environment

The surrounding air and installation conditions matter. LEDs installed in enclosed fixtures or poorly ventilated areas suffer from reduced cooling efficiency.

How Heat Moves in an LED System

Heat transfer in LEDs follows three primary mechanisms:

- Conduction – Direct transfer through solid materials (chip to substrate).

- Convection – Heat is carried away by moving air across a heat sink.

- Radiation – Minor role in LEDs, but some infrared radiation contributes.

The LED lighting thermal path efficient heat dissipation design aims to optimize all three, with conduction and convection being most critical.

Design Strategies for Efficient Heat Dissipation

1. Optimize PCB Design

Using metal-core PCBs and optimizing trace layout ensures rapid conduction.

2. Choose the Right Heat Sink

- Passive aluminum fins for standard fixtures.

- Active cooling (fans, liquid cooling) for high-power LEDs.

3. Use High-Quality Thermal Interface Materials

Well-applied TIMs can reduce thermal resistance by up to 50%.

4. Consider Fixture Enclosure Design

Ventilation slots, airflow channels, and reflective surfaces enhance cooling.

5. Smart Driver Design

LED drivers should also be thermally managed, since they generate their own heat.

Case Study: Street Lighting Applications

Streetlights use high-power LEDs that operate for 10+ hours daily. Manufacturers design their fixtures with:

- Large finned heat sinks exposed to airflow.

- MCPCBs with optimized copper layers.

- Durable coatings that protect against dust and moisture while maintaining thermal performance.

This ensures the LED lighting thermal path’s efficient heat dissipation is reliable even under outdoor temperature extremes.

Measuring and Testing the Thermal Path

Engineers verify thermal performance with methods like:

- Infrared thermography to visualize heat spread.

- Thermocouples to measure junction and case temperatures.

- Thermal simulation software to predict hot spots before manufacturing.

Standards such as JEDEC JESD51 guide measurement consistency.

Common Mistakes in LED Thermal Design

- Ignoring TIM quality – Cheap adhesives lead to poor heat transfer.

- Overloading fixtures – Packing too many LEDs without heat considerations.

- Poor airflow planning – Enclosures that trap heat shorten LED life.

Emerging Trends in LED Thermal Management

- Graphene and Nano-materials – Offering ultra-high conductivity.

- Heat pipes and vapor chambers – Used in advanced applications like automotive lighting.

- Smart thermal sensors – Integrated into drivers to adjust current based on temperature.

These innovations ensure that future LEDs will have an even more reliable thermal path and efficient heat dissipation.

Practical Tips for Installers and Designers

- Always check the manufacturer’s thermal resistance data (RθJA).

- Ensure proper airflow around LED fixtures.

- Avoid cheap retrofit solutions with poor heat sinks.

- Use quality power supplies with thermal protection features.

Conclusion

The LED lighting thermal path, with efficient heat dissipation, is the backbone of reliable LED technology. Without it, LEDs lose brightness, change color, or fail prematurely. By carefully designing the thermal path—from junction to ambient environment—engineers ensure LEDs live up to their promise of high efficiency and long service life.

For manufacturers, installers, and even end-users, understanding this process leads to smarter decisions in lighting design and selection. As innovations like graphene heat spreaders and vapor chambers become mainstream, the future of LED lighting looks even brighter—and cooler.