LEDs are widely known for their high efficiency, long lifespan, and versatility across industries. However, one crucial parameter often overlooked is the LED junction temperature, which affects LED performance. Junction temperature (commonly referred to as Tj) plays a pivotal role in determining the efficiency, reliability, and longevity of LEDs. Managing this parameter is not just a technical consideration — it is the key to unlocking the true potential of LED technology.

In this detailed guide, we’ll explore what LED junction temperature is, why it matters, how it impacts LED performance, and proven methods to control it.

What Is LED Junction Temperature (Tj)?

LED junction temperature is the temperature at the point where the LED emits light. More specifically, it is the temperature inside the semiconductor junction where the electrical energy converts into light and heat.

- Tj (junction temperature): Internal LED temperature at the p-n junction.

- Tc (case temperature): The temperature on the LED package or case.

- Ta (ambient temperature): The surrounding environment temperature.

Since LEDs are not 100% efficient, a significant portion of the energy is converted into heat instead of light. This heat accumulates in the junction, raising Tj. If not properly managed, elevated Tj can significantly degrade LED performance.

Why LED Junction Temperature Affects LED Performance

The LED junction temperature affecting LED performance is critical because excessive heat influences multiple aspects of an LED’s operation:

- Luminous Efficiency Drop

Higher junction temperature reduces the LED’s light output. For every degree Celsius increase in Tj, light output can drop significantly (varies by LED design). - Color Shift

Elevated Tj causes spectral shifts, altering the color of emitted light. This is problematic for applications requiring precise color rendering, such as displays, automotive lighting, or architectural illumination. - Reduced Lifespan

Heat accelerates material degradation inside the LED chip and phosphor. Operating at high Tj shortens LED lifespan, sometimes by thousands of hours. - Increased Power Consumption

LEDs at higher Tj require more current to maintain brightness, reducing efficiency. - Thermal Runaway Risk

Poor heat dissipation can cause a vicious cycle: higher Tj increases resistance, which generates more heat, leading to eventual LED failure.

Typical LED Junction Temperature Ratings

Most LEDs are designed with a maximum junction temperature between 125°C and 150°C. Exceeding these ratings leads to rapid degradation.

- Optimal range: Below 85°C

- Maximum allowable: 125–150°C (depending on manufacturer)

For best performance and longevity, LEDs should be kept well below the maximum Tj.

(Reference: Cree LED Reliability Data)

How to Measure LED Junction Temperature

Measuring junction temperature is not as straightforward as measuring surface or ambient temperatures. Here are the common methods:

- Forward Voltage Method (VF): Uses the change in forward voltage with temperature.

- Infrared (IR) Thermography: Captures surface heat distribution and estimates Tj.

- Thermocouples: Measure case temperature and calculate junction temperature using thermal resistance values.

Manufacturers often provide thermal resistance data (junction-to-case, junction-to-ambient) to help engineers calculate Tj accurately.

The Science Behind LED Junction Temperature

Understanding the LED junction temperature affecting LED performance requires exploring the physics inside the LED:

- When current flows through the diode, electrons recombine with holes, releasing photons (light).

- However, not all recombinations emit photons. Many generate phonons (heat).

- This heat accumulates at the semiconductor junction.

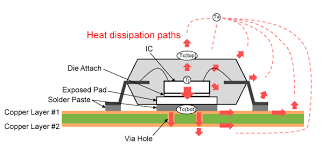

- If the heat is not effectively conducted away (via thermal paths), Tj rises quickly.

This explains why thermal design is a cornerstone of modern LED engineering.

Key Factors Influencing LED Junction Temperature

Several conditions contribute to higher Tj values:

- Ambient Temperature (Ta): Hot environments raise baseline operating temperature.

- Current Drive: Higher drive currents increase both light output and heat.

- Package Design: Poor thermal conductivity materials trap heat.

- Heat Sink Quality: Inefficient heat sinks fail to move heat away.

- PCB Material: Metal-core PCBs (MCPCBs) are superior for thermal management.

- Enclosure Design: Poor airflow or sealed housings worsen heat buildup.

Effects of LED Junction Temperature on Performance

Here’s a summary of the direct effects:

- Light Output: Drops as Tj increases.

- Wavelength Shift: Causes visible color changes.

- Reliability: Reduced by accelerated degradation.

- Efficiency: Lower lumens per watt.

- Consistency: In multi-LED systems, uneven heating leads to color mismatch.

(Further reading: Osram LED Thermal Management)

Thermal Management Solutions

Keeping the LED junction temperature affecting LED performance under control requires multiple design strategies:

1. Heat Sink Design

- Aluminum or copper heat sinks absorb and dissipate heat.

- Larger surface area improves convection cooling.

2. Thermal Interface Materials (TIMs)

- Thermal pastes, pads, or adhesives improve conduction between the LED and the heat sink.

3. PCB Design

- Metal-core PCBs (MCPCBs) reduce thermal resistance.

- Thicker copper layers help conduct heat away.

4. Active Cooling

- Fans or liquid cooling systems for high-power LEDs.

- Used in projectors, automotive headlights, and industrial lighting.

5. Drive Current Management

- Lowering the current reduces Tj and increases LED lifespan.

- Smart drivers can adapt current based on temperature feedback.

Real-World Applications Where Junction Temperature Matters

- Street Lighting – Outdoor temperatures and enclosed fixtures require robust thermal management.

- Automotive LEDs – Headlights face high currents and sealed housings.

- Display Technology – Color stability is critical; even small Tj shifts can cause visible defects.

- Medical Devices – Require consistent illumination and long-term reliability.

- Industrial & Hazardous Areas – High ambient temperatures demand strict Tj control.

Conclusion

The LED junction temperature affecting LED performance is one of the most critical aspects of LED technology. From brightness and color stability to overall lifespan, Tj dictates whether an LED system will thrive or fail. By understanding the science behind junction temperature and implementing effective thermal management solutions, engineers and designers can ensure LEDs deliver their full promise of efficiency and durability.

Whether you’re designing street lighting, display systems, or automotive headlights, keeping Tj under control ensures long-lasting, reliable illumination.